|

| Specification : |

|

Simple low-cost and compact models, easy to operate and maintainAutomated production, low labor costs and avoid artificial ingredients ingredients error

All the design and manufacture of tailor mirror polished

User-friendly LCD touch screen, easy to set various parameters

Can be used with material handling systems

Quick start operation and replacement of the mother of Joseph and additives

Metering valve are taken, under a two-stage control of the material collected, accuracy up to <= 0.3% GS SERIES Specification Table

GS

SERIES

|

|

GS-06

|

GS-15

|

GS-30

|

GS-60

|

GS-90

|

|

|

Production capacity

|

150Kg/HR

|

300Kg/HR

|

600Kg/HR

|

1000Kg/HR

|

1500Kg/HR

|

|

|

Weight tank

|

6Liter

|

15Liter

|

30Liter

|

60Liter

|

90Liter

|

|

|

Feeding mode

|

Two-stage valve

|

Two-stage valve

|

Two-stage valve

|

Two-stage valve

|

Two-stage valve

|

|

|

Mixing tank

|

15Liter

|

20Liter

|

50Liter

|

80Liter

|

110Liter

|

|

|

Load cell

|

2sets

|

2sets

|

2sets

|

3sets

|

3sets

|

|

|

Programmable Logic Controller

|

Mitsubishi

|

Mitsubishi

|

Mitsubishi

|

Mitsubishi

|

Mitsubishi

|

|

|

5.7"touch panel

|

Mitsubishi

|

Mitsubishi

|

Mitsubishi

|

Mitsubishi

|

Mitsubishi

|

|

|

Recipe memory

|

30sets

|

30sets

|

30sets

|

30sets

|

30sets

|

|

|

Maximum kinds of raw materials

|

6

|

6

|

6

|

6

|

6

|

|

* The capacity of bulk density 0.65KG / LT estimates, the actual capacity varies depending on material

properties

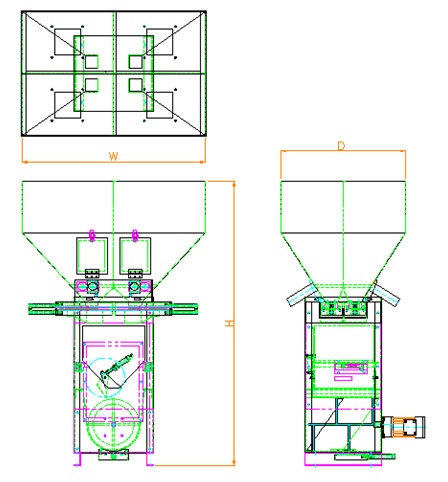

Dimension

|

|

GS-06

|

GS-15

|

GS-30

|

GS-60

|

GS-90

|

|

H(mm)

|

1150

|

1350

|

1450

|

1550

|

1800

|

|

W(mm)

|

600

|

800

|

800

|

1100

|

1250

|

|

D(mm)

|

600

|

800

|

800

|

1100

|

1250

|

*Products subject to change without notice.

|

|

|